The vast majority of special-shaped insert machines on the market can only deal with a small number of components in a

specific size range, and the efficiency is low. This will make the production process management complex and can not

effectively balance the efficiency of the production line.

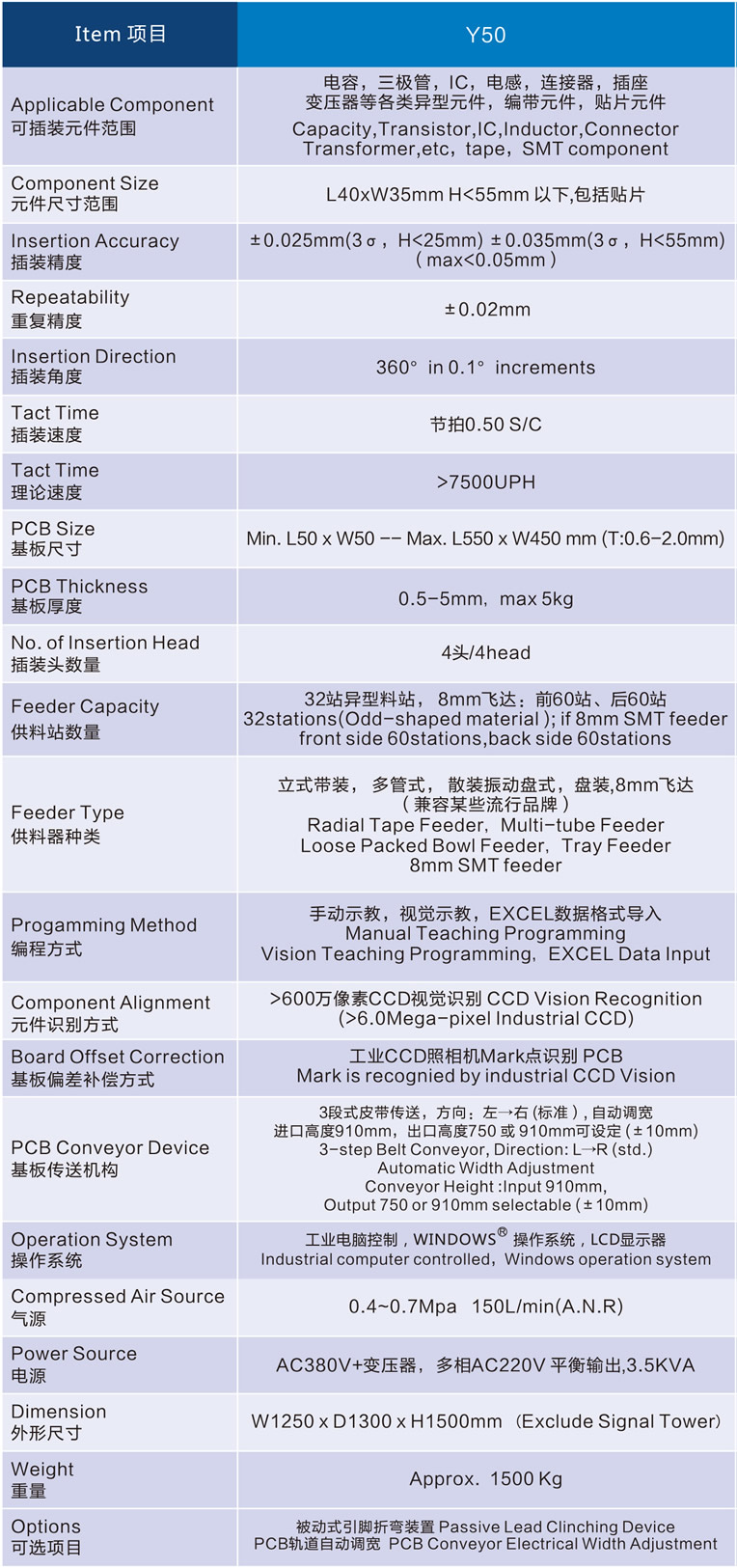

You need solutions with more process compatibility and higher system productivity to break this bad situation.The Y50/Y60 series multifunctional modular special- shaped insert machine newly launched by Techwin has successfully overcome the problems of the combination of speed and flexibility, compatibility and efficiency. Its unique innovative technological revolution integrates low maintenance linear motor, high-resolution digital camera and advanced optical sensor. It still shows excellent performance and extraordinary production efficiency in a compact unit space. This means that you no longer have to compromise the efficient productivity of the whole line for the special- shaped component insert process that hinders the operation of the system for a long time. At the same time, its modular structure design allows you to arrange the production line according to the growing process demand at any time. AlI these technologies and functions that keep pace with the times are only to keep your investment more long - term value.

Y50/Y60 series special- shaped insert machine has successfully overcome the process problem of the combination of high speed and versatility that was still a challenge yesterday. It can realize thousands of components of automatic insert, covering components of various sizes ranging from 5mm * 5mm to 150mm * 80mm, and even components weighing 400g.

You need solutions with more process compatibility and higher system productivity to break this bad situation.The Y50/Y60 series multifunctional modular special- shaped insert machine newly launched by Techwin has successfully overcome the problems of the combination of speed and flexibility, compatibility and efficiency. Its unique innovative technological revolution integrates low maintenance linear motor, high-resolution digital camera and advanced optical sensor. It still shows excellent performance and extraordinary production efficiency in a compact unit space. This means that you no longer have to compromise the efficient productivity of the whole line for the special- shaped component insert process that hinders the operation of the system for a long time. At the same time, its modular structure design allows you to arrange the production line according to the growing process demand at any time. AlI these technologies and functions that keep pace with the times are only to keep your investment more long - term value.

Y50/Y60 series special- shaped insert machine has successfully overcome the process problem of the combination of high speed and versatility that was still a challenge yesterday. It can realize thousands of components of automatic insert, covering components of various sizes ranging from 5mm * 5mm to 150mm * 80mm, and even components weighing 400g.

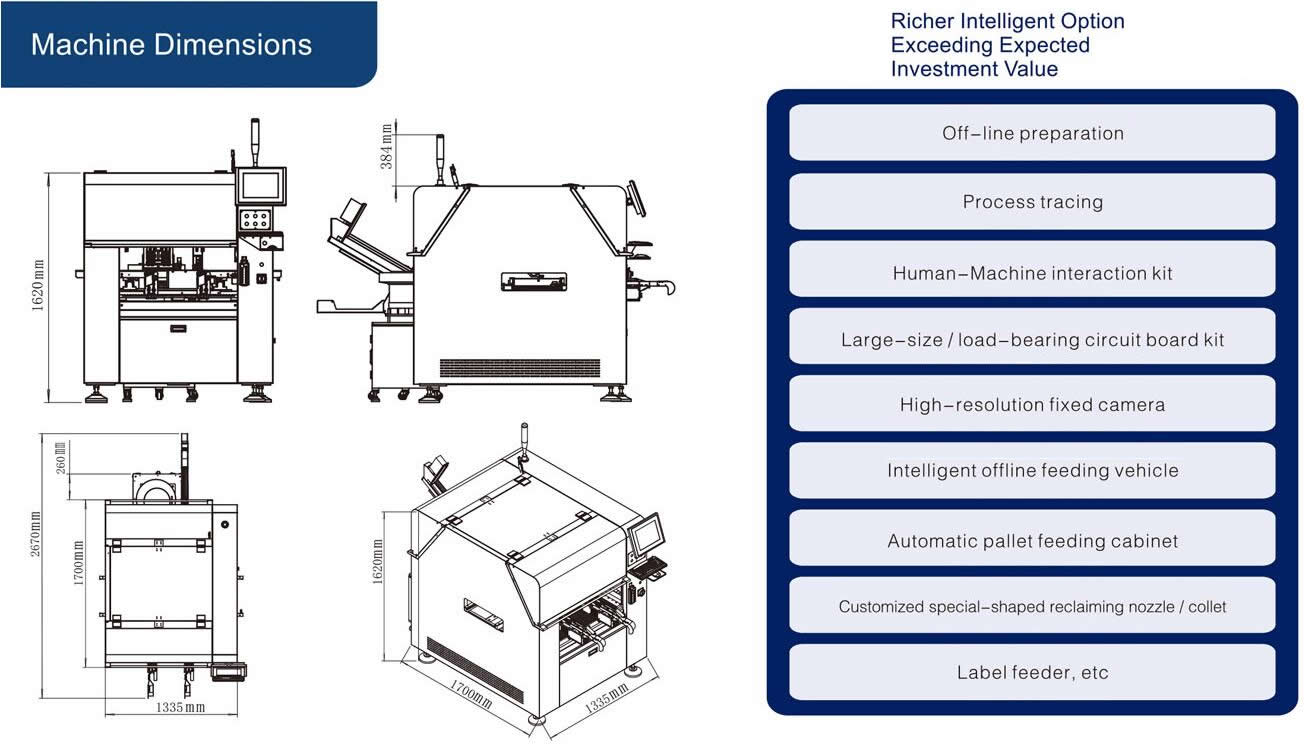

The compact modular design can perform flexibly single machine insertion

tasks. You can merge into the existing production line or configure a new

production line for use, so as to achieve the balance of production capacity

and realize the real value of modular design. The innovation in design and the

use of high-tech materials reduce the weight of the moving cantilever and the

inserting head, and bring agility

with lightness. The X- -axis cantilever is

synchronously driven by a linear motor with a precision grating ruler encoder,

which provides an excellent guarantee for the mechanical accuracy under the

movement of up to 3G gravity acceleration.

Highly Compatible & Diversified Feeder Technology

Extraordinary Insertion Ability Born for Performance

Extraordinary Insertion Ability Born for Performance

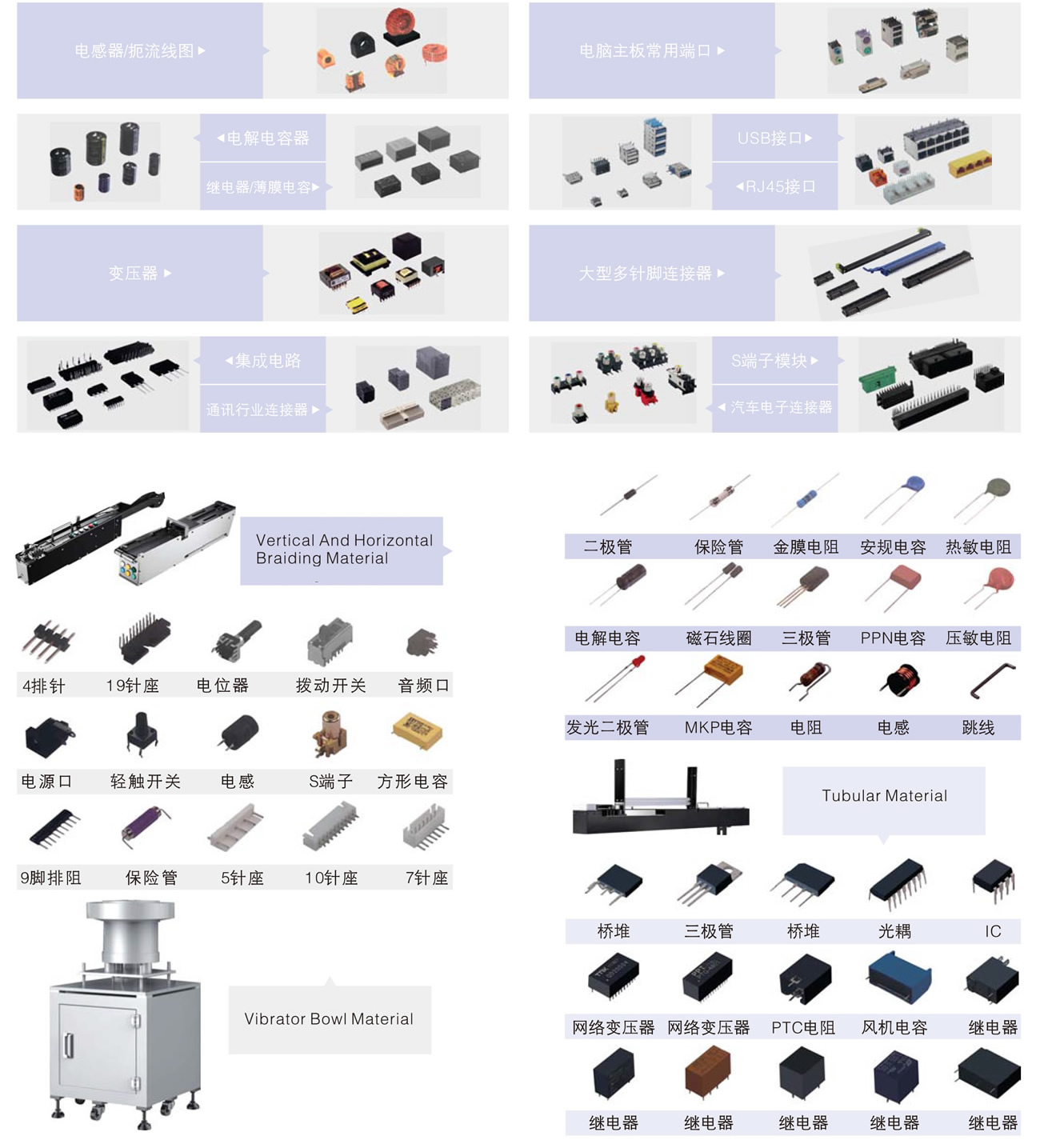

Facing the different types of components of each product and the busy switching rhythm of production line, you need more diversified feeder solutions. In a

compact floor area, Y50 / Y60 has feeder stations that can carry more than 32 different components at most. We have off-line preparation racks that can be loaded

quickly, and single and bilateral feeder configurations are optional; There are also feeder solutions such as tape feeder, matrix tray automatic feeder, tubular feeder

and bulk feeder for you to match. Once the feeder is installed, the system can automatically identify the newly loaded components and produce them at the fastest

speed of 0.32 seconds / piece (different due to the difference of component types). With such excellent on- board component inventory loading and insertion

capacity, you can safely handle the production demand of any order.