K Series Auto High Speed Insertion Machine

The high-precision visual coordinate positioning system calculates the best plug-

in position through the position identification of all holes (2 holes or 3 holes) at the

insertion position, and makes algorithm correction to assist the precision

mechanical pin pin positioning system to realize stable plug-in implantation.

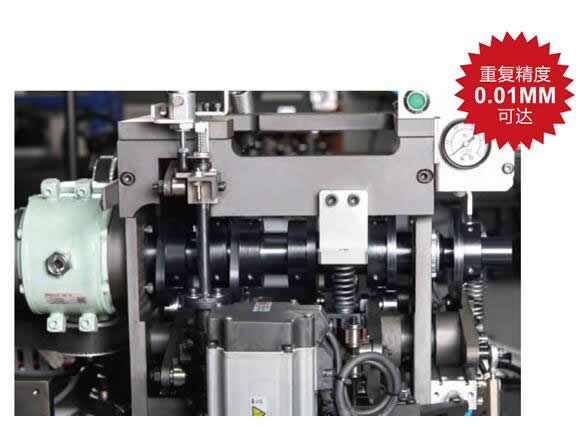

From the machine base, head base and parts to the material station, the integrated

casting process and special stress resistance process are adopted in a wide

range to ensure the overall reliability, cooperate with high-precision machining

components, and realize the more lasting and stable operation of the equipment.

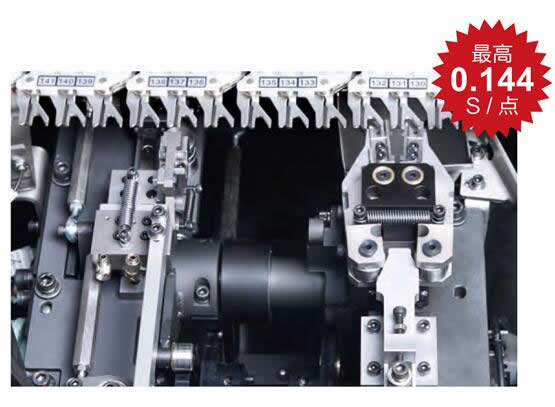

Through the component feeder material used up

automatic inspection

function,timely replenishment of materials to meet high efficiency

production.Material station is designed in a separable way with multiple modes can

be selected to replace materials in the production preparation stage (materials

installation ) and production line replacement, so as to increase the use efficiency.

With fault self diagnosis, the error point can be accurately located in the man-

machine interface, which is convenient for maintenance; The electrical circuit is

simple and easy to understand, and the parameter adjustment of the main control

interface is direct and clear; With strong anti-interference ability and high

transmission accuracy, it is easy to realize after-sales remote control assistance.

New pin paper cutting mechanism with pin shaping to reduce material consumption; Equipped with full-automatic material replenishment and recovery function to automatically deal with plug-in errors to realize non-stop operation; It can also be easily realized for special plug-in requirements such as pin 90 degree bending element, 3.5mm non-standard pin spacing and high-density implantation.

Friendly operation interface, three-level authority setting, easy to deal with daily operation management such as operation command, parameter adjustment and operation information; Structured parameters can be grouped and archived independently to provide the best assistance for your production process; Industry 4.0 centralized management, SPC data statistics, MES port docking and traceability management system (optional) can be easily realized

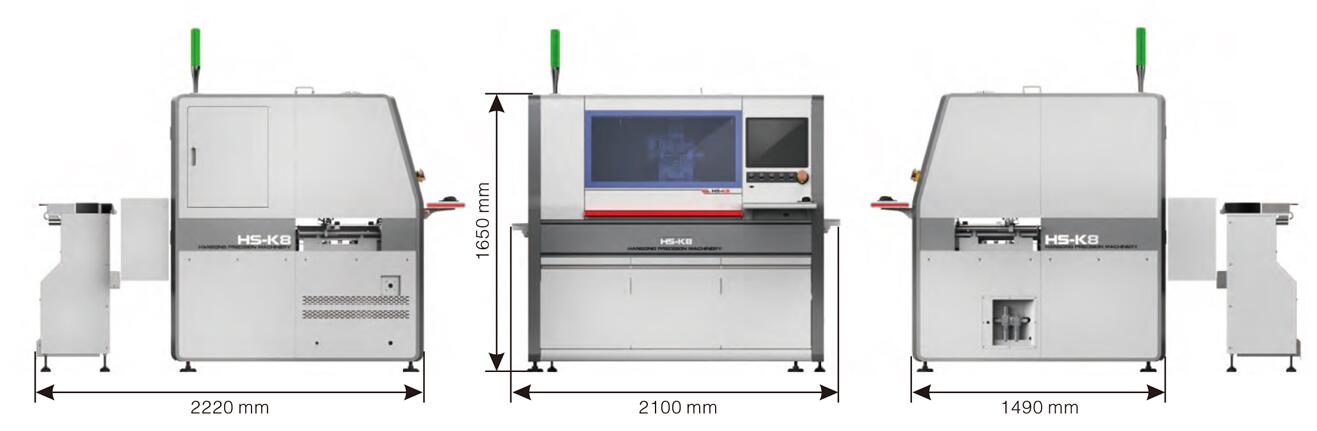

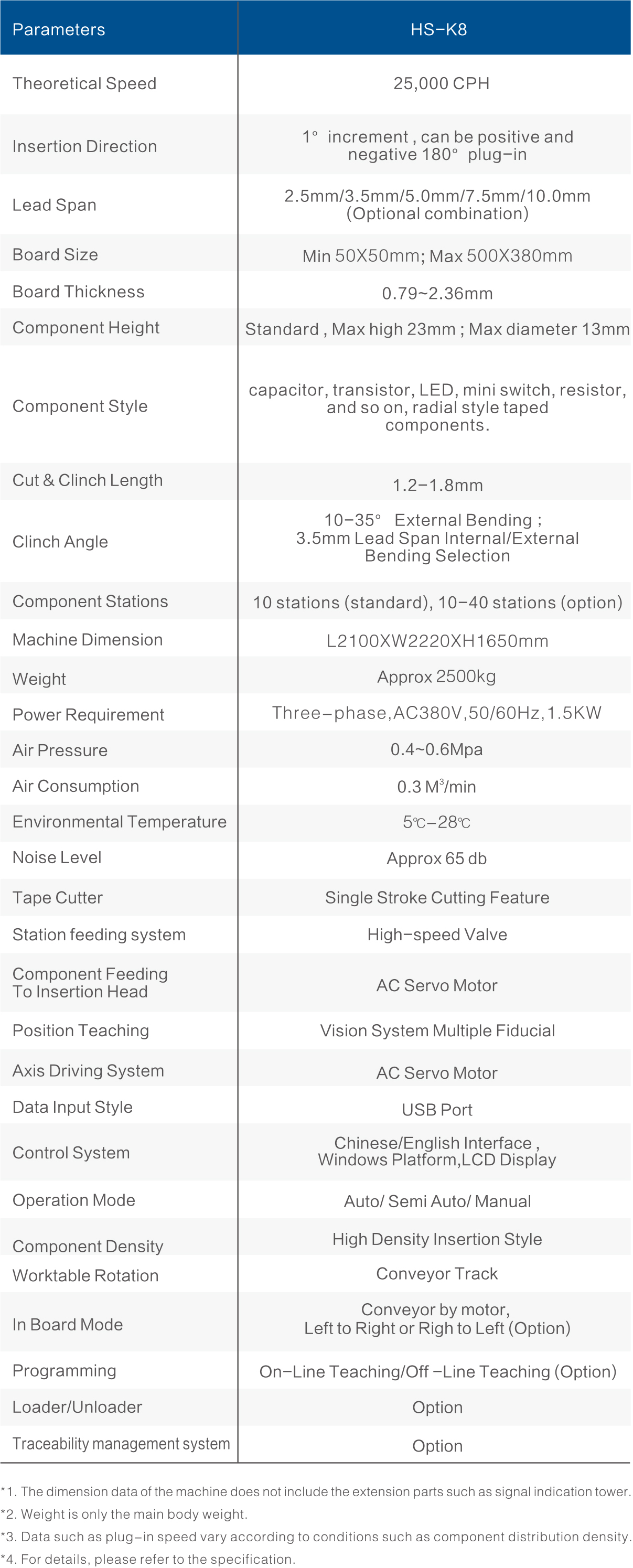

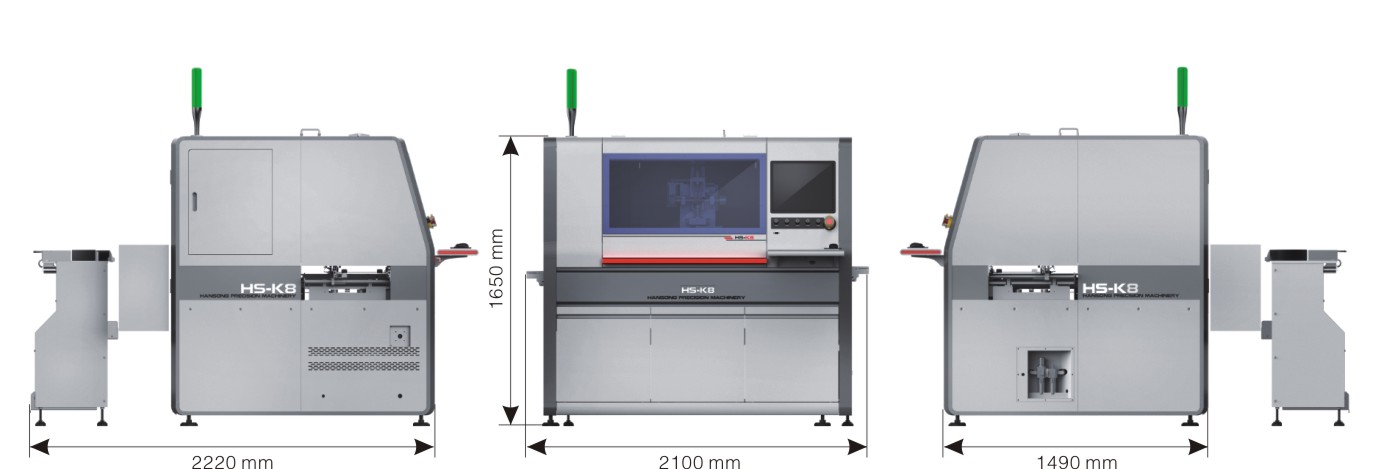

▼ Overall dimension