Patented Furnace & Nozzle System

Devoted to Perfect Soldering

Devoted to Perfect Soldering

The stability of solder temperature is particularly important to soldering quality. The

unique layered heating and temperature control technology of Micropeak Nitro series

wave soldering system, combined with the heater with special copper medium

conduction, can quickly and accurately control the furnace temperature in real time and

reduce the load impact of power grid and energy consumption. The unique ceramic

protective layer furnace can effectively resist metal high-temperature corrosion and

prevent process pollution.

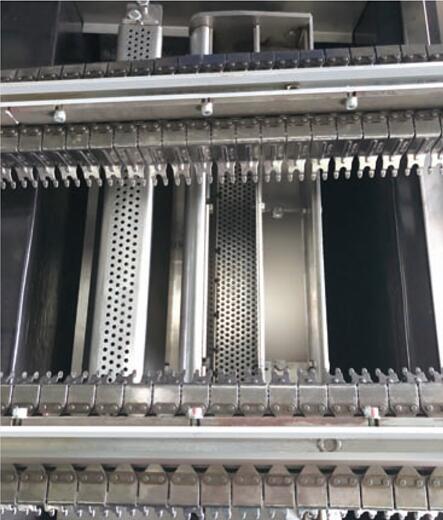

Most of the soldering defects in wave soldering process can be improved by parameter adjustment. A personalized nozzle can greatly improve the adaptability of the process window. Micropeak Nitro series wave soldering system has a unique detachable adjustable nozzle, which can easily adjust a variety of waveforms, flexibly deal with various complex process tests and achieve perfect soldering quality.

► Corrosion resistant furnace

► Accurate and real-time temperature control technology Ensure process stability

► Personalized adjustable nozzle Meet complex process requirements as much as possible

► Disassembly free and low maintenance requirements

► Accurate and real-time temperature control technology Ensure process stability

► Personalized adjustable nozzle Meet complex process requirements as much as possible

► Disassembly free and low maintenance requirements